In Partnership with

Bringing collaborative working in the scaffolding sector to life

As part of our HAKI culture, we view partnerships as a backbone to our operations, and an integral part of our future success. Afterall, it’s how minds combine to solve challenges, and how expertise joins together to deliver better outcomes.

Founded in 1992, Alltask are committed to leading the way on scaffolding and asbestos removal service standards. Their systematic approach, collaborative methodology, new fleet & facilities and in-house design team mean they are go-to for UK’s portfolio major civil and infrastructure projects.

Integral to Alltask’s approach is their extensive and ongoing investment in the HAKI Universal system, which enables bespoke solutions to be tailored to particularly demanding projects.

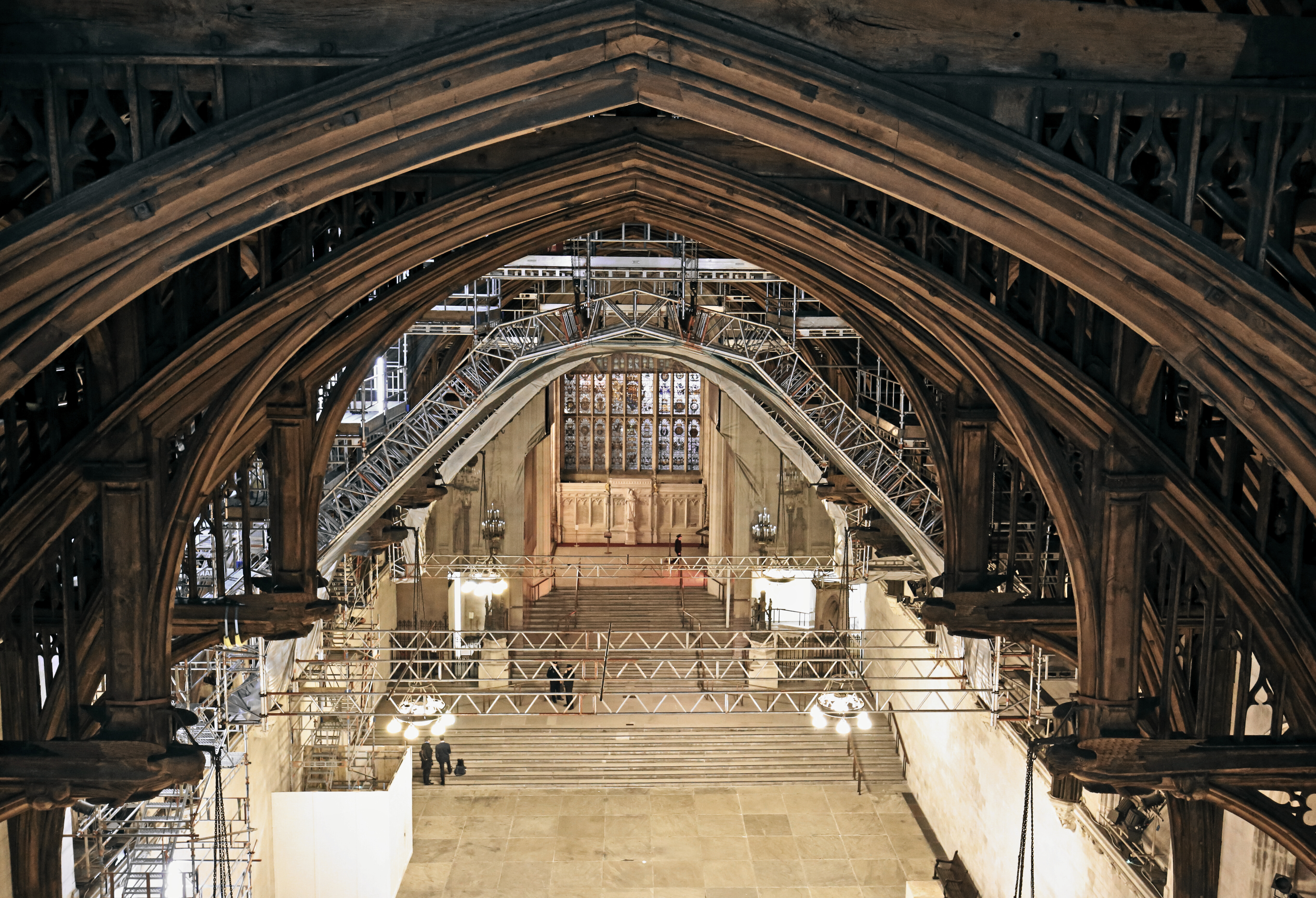

One such project was the ongoing restoration work at The Houses of Parliament, for which Alltask was contracted to carry out an extensive scaffold access package to the inside of Westminster Hall, the oldest building on the parliamentary estate carrying more than 900 years of fascinating history including the trial of Charles I, coronation banquets, the lying-in-state of monarchs and prime ministers and addresses by world leaders.

The main refurbishment works comprised two parts; the first involved the meticulous conservation of the internal roof trusses sited 28m above ground level. This oak hammer-beam roof, commissioned by Richard II in 1393, is the largest in Northern Europe, spanning more than 20 metres. The second part of the works involved the deconstruction and restoration of the external roof lantern. With considerations of the rich history teamed with the irreplaceable nature of the majority of the structure meant that Alltask needed to work closely with the experienced team at HAKI UK.

Together, Alltask and HAKI UK co-developed a lightweight access solution, built at ground level and lifted into position via purpose-built hoists made in Germany specifically for the contract. The roof structure within Westminster Hall is comprised of 14 individual bays, 12 of these bays were suspended via purpose-built HAKI access rigs & bespoke, purpose-made chains, 28m in the air.

With the support of HAKI’s experienced personnel, Alltask’s operatives were trained specifically for this task, so they could understand how to use the HAKI Universal system and why it’s use leads to time-saving efficiencies when working with an order of such high-value components.

HAKI have also been critical to the success of the Alltask project at London Waterloo Station which started in 2020. Design work initially began with a tube and fitting scaffold solution, however, the HAKI Universal systems lightweight nature, quick erection and dismantling times, and superior load-bearing capabilities were a far better option.

HAKI system scaffold supported this project across two key areas and was rolled out firstly to assist in replacing the glazed roofs throughout the station and secondly to link canopy between the stations North and South Port passageways to facilitate the roof replacement works.

Whilst these were complicated design briefs, the projects were perfect demonstrations of how, by working together, even the most complex challenges can be delivered with precision. Alltask and HAKI are looking forward to continuing their mutually-beneficial, collaborative partnership approach on future projects together.